Model No.︰DS

Brand Name︰HXSD

Country of Origin︰China

Unit Price︰US $ 7000 / pc

Minimum Order︰1 pc

Fully Automatic Industrial Puffed Cereals Machine

Introduction of Fully Automatic Industrial Puffed Cereals Machine

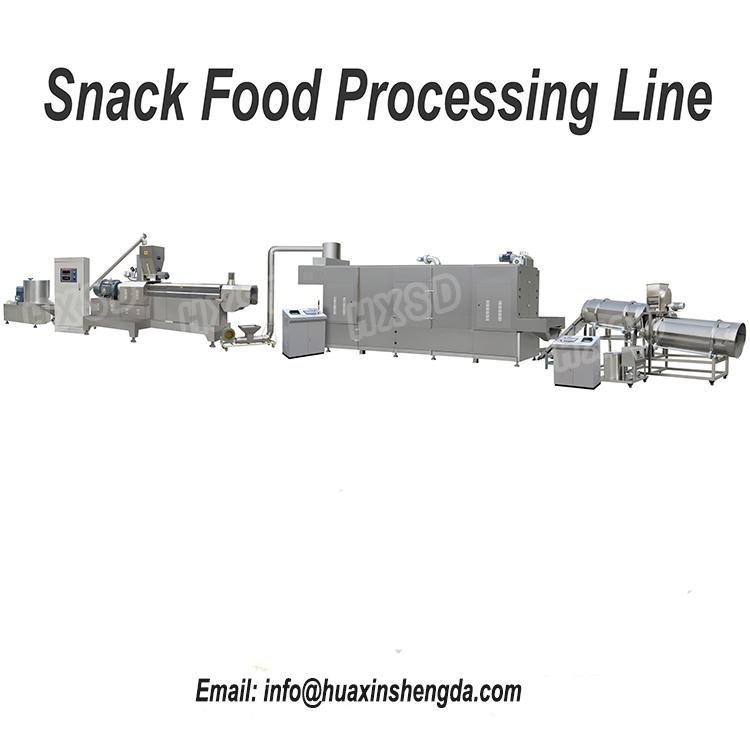

Snacks food machine can be directly extruded from the extruder, dryer and flavoring machine. We can produce all kinds of snacks and different shapes by adjusting the dies from extruder.

Fully Automatic Industrial Puffed Cereals Machinecan take corn, rice, wheat, oat, rye and other grains as materials to produce extruded snacks, with crispy taste and lively shape, Snacks food processing line is designed according to market demand. It includes cheese balls, corn curls, corn sticks, coco pops, cereal, kurkure and pellets.

Products: Variety shapes are available for onion ring, fruit loops, coco loops, corn snacks, cheese balls, corn curls, corn sticks, coco pops, breakfast cereals, corn flakes, kurkure and pellets, etc.

Raw materials: adopts corn, rice, wheat, oat, barley etc as ingredients.

Products: different shapes are made by adjusting the dies from extruder.

parameter

|

Model |

DS65 processing line |

DS70 processing line |

DS85 processing line |

|

Install Power |

65kw |

110kw |

190kw |

|

Consumption Power |

42kw |

77kw |

133kw |

|

Output |

120-150kg/h |

220-260kg/h |

500-600kg/h |

|

Dimension |

1.9*1.3*2.2m |

22*1.3*2.2m |

30*1.3*2.5m |

Flow chart:

Mixing system---Extrusion system---Drying system---Flavoring system---Packing system.

Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

Machines Materials: All theFully Automatic Industrial Puffed Cereals Machine are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

our service

1)Provide factory layout according to your factory size in advance;

2)Provide the basic formula;

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment;

4)Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;

5)Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever;

6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

Company Introduction

Jinan HXSD Machinery Technology Co.,Ltd match production and sales of various types of food processing machinery, feed machinery, modified starch machinery:

1. Corn Flakes & Breakfast Cereals Processing Line

2. Non-Fried Snacks Processing Line

3. Core Filling Snacks Processing Line

4. Nutrition Powder Processing Line

5. Bread Crumb & Snow Flakes Slice Processing Line

6. Soybean Protein & Drawing Protein Processing Line

7. Fried Puffed Snacks & Fried Pasta Processing Line

8. 2D/3D Pellet & Fried Chips Processing Line

9. Nutrient Compound Rice Processing Line

10. Instant Rice Processing Line

11. Extrusion Pasta/ Pasta Processing Line

12. Instant Noodle Processing Line

13. Modified Starch Processing Line

14. Pet Food & Fish Feed Processing Line

15. Dog Chews Processing Line

16. Caramel Popcorn Processing line

17. Cheetos Nik Naks Kurkure Processing Line

17.Series of Extruder

18. Series of Dryer

19. Series of Fryer & Flavor

20. Other Machines

Payment Terms︰ TT/LC/DP